For a more deliberate and targeted focus on continuous improvement, Sunpro recently had 11 leaders pass the Lean Six Sigma exam certifying them as Lean Six Sigma Green Belts.

Certified Lean Six Sigma Green Belts are professionals who are well versed in the advanced elements of Lean Six Sigma, a method that provides organizations with the tools to improve the capability of their business processes. A Lean Six Sigma Green Belt understands how to implement, perform, interpret, and apply Lean S ix Sigma at a high level of proficiency. Each Sunpro leader completed a 100-question proctored exam within a three-hour allotted time.

We are convinced that these trained leaders, supported by trained Lean Six Sigma Green Belt Sunpro executives, a monthly continuous improvement call, and an actively used continuous improvement Teams channel, will elevate Sunpro’s operational efficiency, improve overall engagement and ownership, and make Sunpro a more rewarding and safer place to work.

The following individuals have been tasked with leading continuous improvement efforts for each of the core four Sunpro products:

- Lumber — Jason Barnett & Jason Butterfield

- Truss — Zach Stanley

- Garage Doors & Insulation — Shelby Meinkey

Supporting the Sunpro core four in their areas of expertise are:

- Retail — Brian Johnson

- Systems — Scott Blomquist

- Project Management — Brent Maruji

At the executive leadership level, Greg Templeman, Matt McDonald, and Steve Broadbent were also certified.

Here are some exciting recent activities reported on the Continuous Improvement Teams channel:

From Sunpro’s Retail Operations: Storage rooms were organized more efficiently, and several bins were placed on shelves and labelled to make everything much easier to find.

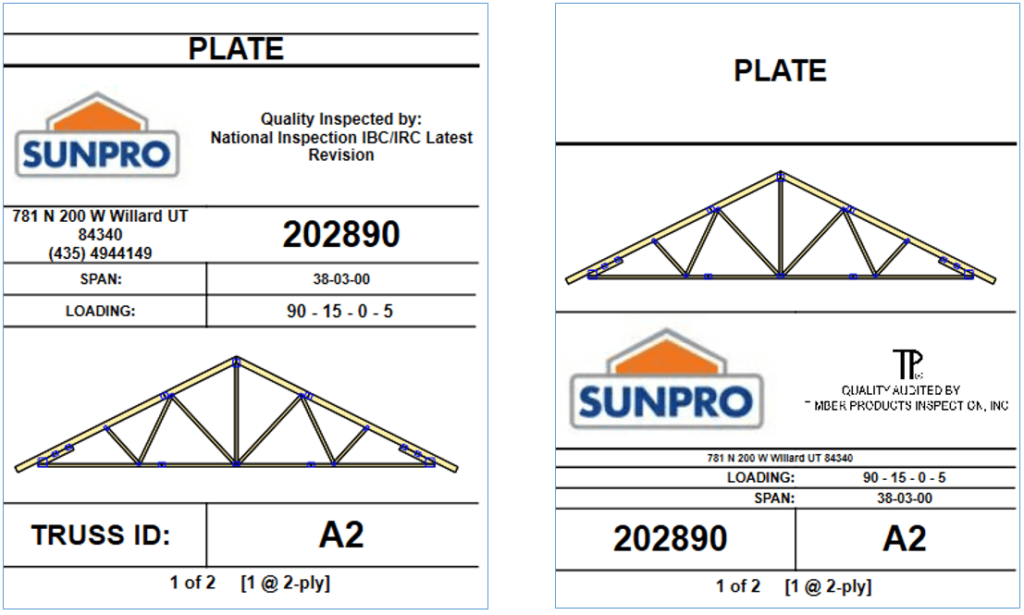

From Sunpro’s Design Team: Truss label tags were redesigned with the order number placed at the bottom of the tag to help in the identification process. Additionally, shortcuts were implemented in the computer applications they use every day to save time.

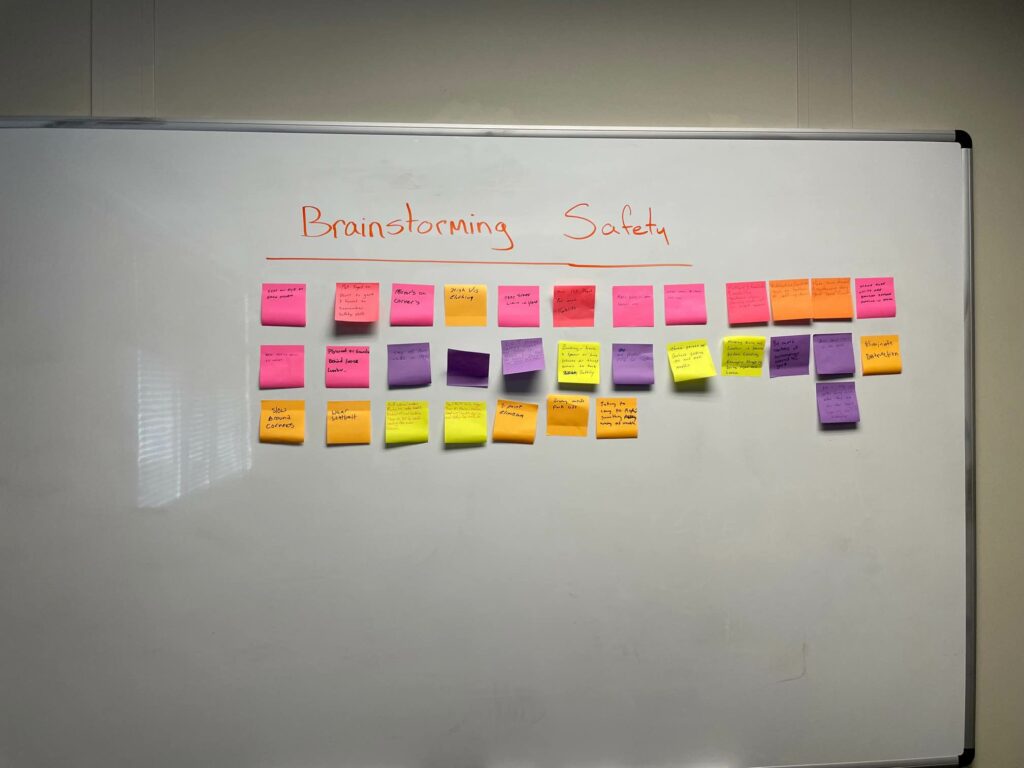

From Sunpro’s Salt Lake City Lumber Location (Safety and Production Ideas): The team conducted a brainstorming session during a regularly held safety meeting to improve processes for themselves and customers. Many of the ideas have already been implemented to help increase safety and productivity in the workplace.

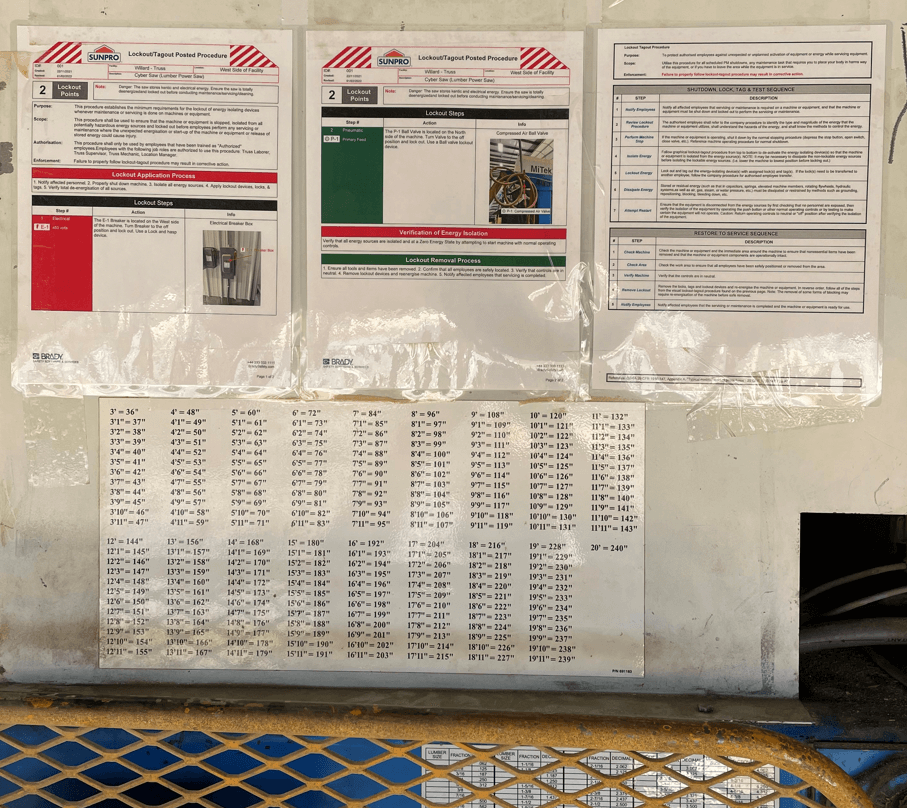

From Sunpro’s Willard Location (Safety): The Willard team has worked to update safety on all saws — including adding specific lock out, tag out documentation and training. Reviewing cleaning procedures and painting new safety lines have also been prioritized.